Ace Alpha is a Supplier of custom spiral wound gaskets. Ace-Alpha -engineered spiral wound gaskets are ideal for applications that demand a gasket with the highest-quality flexibility and recovery to maintain a seal even in conditions characterized by fluctuating temperature and pressure.

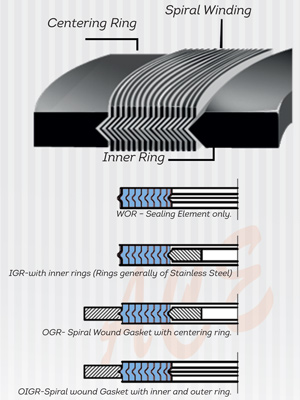

Composed of a steel centering (outer) ring, a spiral wound sealing strip (filler) and an inner ring made of special steel, spiral wound gaskets are created by winding alternating strips of metal and filler material. Depending on the chemical compatibility requirements, the filler and winding material can be changed.

The spiral wound gasket depends upon the mechanical characteristics of a formed metal spiral strip, rather than the compressive virtues of more traditional gasket materials. This makes it particularly suitable for low or fluctuating bolt loads. The sealing strips, or fillers, are usually graphite, although other materials such as PTFE , Non Asbestos, ceramic., may be used, the windings are always s/steel

These gaskets are manufactured to International specifications such as ASME, DIN, JIS, BS We also manufacture to customer's specifications

| WOR | Spiral Wound Metaillic Gasket- sealing element only - without guide and Inner ring |

| IGR | Spiral Wound Metallic Gasket with inner ring (Inner rings generally of stainless steel) |

| OIGR | Spiral Wound Metallic Gasket with Guide (outer) ring. (Centering ring made of carbon steel ,stainless steel and other metals) |

| OGR | Spiral Wound Metallic Gasket with inner & outer rings. (Rings are made of carbon steel stainless steel and other metals) |

Spiral wound gaskets are used in Refinery, Petrochemical, Chemical, Steam lines and Process Industries, where they have many advantages over older types of gaskets.

FLANGE STANDARDS SOR, SIO, SIOH, SIR type spiral wound gaskets can be manufactured in accordance with all relevant gasket standards and specifications to suit the following

| ASME/ANSIB16.5 | MSS SP44 (ASME B16.47 SERIES A) (AWWA) |

| BS 1560, BS10, BS4504 | DIN FLANGES, JIS FLANGES |

| API 605 (ASME B16.47 SERIES B) | FRENCH NF STANDARD |

| FILLERS MATERIALS | MAX. WORKING TEMPERATURE |

|---|---|

| Graphite Mica | 350 F (Temperature) |

| Graphite 99.8% purity | 1200 C |

| Non asbestos | 550 C |

| PTFE | 250 C |

| Ceramic | 1000 C |

| SS304 | 650 Deg C |

| SS316 | 800 Deg C |

| SS347 | 870 Deg C |

| SS321 | 870 Deg C |

| Monal400 | 800 Deg C |

| Nickel 200 | 600 Deg C |

| Titanium | 540 Deg C |

| Iconel600 | 1000 Deg C |

| Inconel625 | 1000 Deg C |

| Incoloy825 | 1000 Deg C |

Carbon Steel, Stainless Steel 304,304L, 316,316L,316Ti,321,347, MONEL® 400,Inconel® 600,625,800, Incoloy® 800, 825, Nickel 200, Titanium, Hastelloy, Copper.

Size & Shape as per Prevailing International standards or Customer needs can be produced.

| Nom. Thickness | Compressed Thickness |

|---|---|

| 2.5 mm(.098 in) | 1.9/2.1mm(.075/.085 in) |

| 3.2 mm(.125 in) | 2.4/2.6mm(.095/.105 in) |

| 4.5 mm(.175 in) | 3.2/3.45mm(.125/.135 in) |

| 6.4 mm(.250 in) | 4.6/4.8mm(.180/.190 in) |

| 7.3 mm(.285 in) | 4.7/4.9mm(.185/.195 in) |

The centering ring does not come into direct contact with contained fluid. It is normally of carbon steel and electro plated to avoid corrosion. Other materials are available on request.

Inner ring used to avoid excessive compression due to high seating stress in hig pressure service and it is also used to reduce turbulence in the flange area. It is normally made of the same material as the gasket metallic strip.