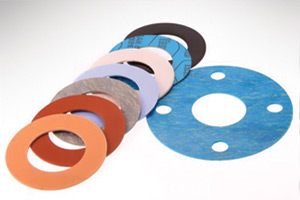

ACE- Alpha products offers a wide range of gasket materials. They can be used for specific industrial applications and are all available in different gasket sheet sizes in order to provide the most suitable sealing solution for our customers.

Selection of the most appropriate gasket material strongly depends on several factors such as pressure, operating temperature, media, chemical composition ,type of flange, number of bolts.

Compressed Non Asbestos Synthetic Fibers gasketing materials (CSF), OrganicFibres, Aramid Fibres, Glass Fibres, Carbon Fibres, Mineral Fibres, etc.,

Available with additional improvements: Graphite coating, PTFE & Anti stick coating, With wire reinforcement on request.

| Std.LineType | Composition | Max T (C/F) | Max P.(bar/ psi) | Properties & application | |

|---|---|---|---|---|---|

| BA - 202 | Organic Fibres, NBR | Peak Continuous |

180/356 140/284 |

40/580 | Good resistance to water, gases,oils,fuels at lower loading |

| BA - 203 | Aramid fibers, NBR | Peak Continuous |

250/482 200/392 |

50/725 | Good resistance to water, gases,oils, fuels at medium loading |

| BA - 50 | Aramid fibers, NBR | Peak Continuous |

280/536 220/428 |

80/1160 | Good resistance to water, gases, fuels, food industry and oils good dynamic resistance for higher loading- WRAS/WQc, approved |

| BA - 55 | Synthetic fibers, NBR | Peak Continuous |

350/662 270/518 |

100/1450 | excellent and economical solution for a wide range of applications |

| BA - U | Aramid fibers, NBR | Peak Continuous |

350/662 250/482 |

100/1450 | Excellent gasket material for general use with extremely wide application range.- WRAS/WQc, |

| BA - GL | Glass fibers, NBR | Peak Continuous |

440/824 350/662 |

100/1450 | Sealing of very broad range of media at high temperatures. |

| BA - CF | Carbon fibers, NBR | Peak Continuous |

400/752 300/572 |

100/1450 | Sealing of steam and very aggressive media in chemical and petrochemical industries |

| BA - Auto | Aramid fibers, SBR | Peak Continuous |

280/536 220/428 |

80/1160 | Sealing at low surface stresses in automotive and chemical industry |

| BA - N | Aramid fibers, CR | Peak Continuous |

350/662 270/518 |

100/1450 | Sealing of different applications in the refrigeration industry |

| BA - C | Aramid fibers, CSM | Peak Continuous |

200/392 150/302 |

60/870 | Sealing of extremely aggressive media in many industries |

| BA - R | Aramid fibers, NBR, wire reinforced | Peak Continuous |

400/752 350/662 |

140/2030 | Applications where resistance to the high dynamic loadings is the premium requirement |

| BA - R300 | Inorganic, NBR, wire reinforcement | Peak Continuous |

550/1022 450/842 |

500/7251 | extreme dynamic conditions in the automotive industry, petrochemical industryand shipyards |

| BA - 302 | Inorganic fibers, NBR, special reinforcement | Peak Continuous |

650/1202 600/1112 |

500/7251 | The most demanding requirements in automotive industry, petrochemical industry & shipyards |

Dimensions of standard Sheet

Sheet size(mm): 1000 x1500 , 1500 x 1500, 3000 x 1500, 4500 x 1500

Thickness(mm): 0.5 , 0.8, 1.0, 1.5, 2.0, 3.0, 4.0, 5.0

Other dimensions and thickness on request.

Download PDF