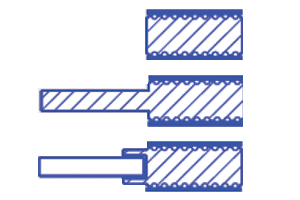

Ace Alpha provider of high-quality camprofile gaskets. Consisting of a metal core serrated on each side and covered with a soft filler that is bonded to each face, our camprofile gaskets are ideal for both standard pipe and heat exchanger applications.

Camprofile gaskets are used in applications where high pressures and temperatures are maintained and consequently high bolt loads need to be controlled.

For flange protection the Camprofile gaskets are normally used in conjunction with a covering layer of either PTFE, Graphite etc, and provided that the layer thickness is correct in application the flange will be completely protected from the grooved profile of the gasket.

Power plants/ petrochemical and chemical industries