ACE Alpha Ring joint gaskets are solid metal gaskets and are used with stand high pressure and temperature, and they are employed where corrosive agents are presented. It is recommended that the gasket material be softer than the mating flanges. Some types of ring joint gaskets are activated when high pressure is presented; that means the higher the pressure, the better the sealability. To ensure a proper sealing the surface of contact between gaskets and flange has to be carefully processed.

They are widely used in the Oil & Gas, Petrochemical and offshore industry and in valves and pipe work. Choice of material may be determined to suit higher temperatures and aggressive media. They comply with ASME B16.20 standards and API spec 6A.

| Type | Nominal Pipe Size | Class Rating |

|---|---|---|

| R- Series Oval & Octagonal Ring no R11 to R105 |

1/2 “ – 24” | 150 TO 2500 ASME B 16.20 |

| 26” – 36” | 300 TO 900 ASME B 16.20 Series A | |

| 1 1/2” -20” | API 6A | |

| RX- Series Available Ring no RX 20 to RX 215 |

1/2 “ – 24” | 750 TO 5000 ASME B 16.20 |

| 26” – 36” | 300 TO 900 ASME B 16.20 Series A | |

| 1 1/2” -20” | API 6A | |

| BX- Series Available Ring no BX 150 to bX 172 |

1 11/16”- 21 ¼” | 5000 to 20000 ASME B 16.20 |

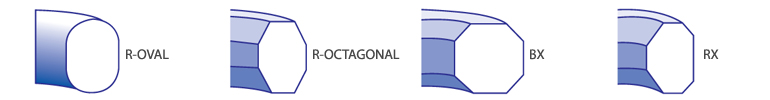

The contact face is in oval shape. It provides a high reliability seal. These gaskets comply with ASME B-16.20.

More accurate in dimensions and surface finish than oval type because it consists of straight surfaces only. A Higher torque load is required to flow the gasket material into imperfections of the flange facings. These gaskets comply with ASME B-16.20.

Designed to API 6A. Interchangeable with the oval and octagonal series of identical reference numbers, and used in the same flange grooves.

Designed to API 6A for use with grooved flanges for special applications involving high pressures from 5,000 to 15,000 psi.

The metal ring joint gaskets have been designed to withstand exceptionally high assembly loads over a small area, thus producing high seating stress.

The octagonal cross section has a higher sealing efficiency than the oval and would be the preferred gasket.

| ASTM | DIN Material No | Maximum HB | Maximum HV | Material Code |

|---|---|---|---|---|

| Soft Iron | 1.1003 | 90 | 56 | D |

| Low CS | 1.0038 | 120 | 68 | S |

| 4-6 Cr 1/2Mo | 1.7362 | 130 | 72 | F5 |

| AISI 410 | 1.4000 | 170 | 86 | S 410 |

| AISI 304 | 1.4301 | 160 | 83 | S 304 |

| AISI 316 | 1.4401 | 160 | 83 | S 316 |

| AISI 347 | 1.455 | 160 | 83 | S 347 |